The new Alvetex® Advanced platform has been developed to complement the existing Alvetex® product line, providing researchers with greater flexibility and functionality while retaining the proven advantages of the Alvetex® scaffold. This system enables the creation of highly reproducible 3D engineered human skin models suitable for pharmaceutical, chemical, cosmetic, and device testing.

Key Advantages of Alvetex® Advanced

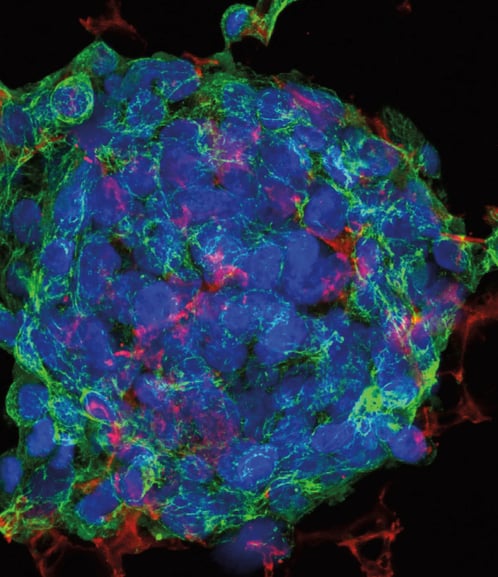

At the core of Alvetex® Advanced is the Alvetex® scaffold, which provides a porous three-dimensional structure that enables mammalian cells to retain their natural morphology and form physiologically relevant interactions. Cells grow not only on the scaffold surface but also within its voids, creating complex tissue-like architectures that closely mimic the properties of native human skin. This biological accuracy underpins the reliability of the system in predictive toxicology and efficacy testing.

The platform is designed with flexibility in mind. Inserts containing skin models can be transferred between different plate formats without disruption, making it straightforward to adapt experiments to varying throughput requirements. Specially designed interchangeable handles can be clipped to inserts, allowing precise control of insert depth, culture medium volume, and simple adjustment to the air–liquid interface. In addition, the system supports both individual culture wells and larger tray formats, where multiple models can share a common medium bath. This versatility enables researchers to tailor experimental conditions to the needs of specific studies.

A defining feature of Alvetex® Advanced is the accessibility of the epidermal surface. Throughout the culture period, the skin surface can be reached easily for the application of topically administered compounds, devices, or measurement probes. This design also facilitates specialized manipulations, such as generating controlled wounds for healing studies, performing exfoliation procedures like tape stripping, or subjecting the tissue to defined doses of UV irradiation for sunscreen assessment. To ensure accurate testing, an innovative tissue seal between the upper and lower compartments prevents leakage and eliminates the common “edge effect” observed in other systems.

The system also supports a wide range of functional measurements that can be performed non-invasively during culture. Parameters such as transepidermal water loss (TEWL), pH, dye penetration, and transepithelial electrical resistance (TEER) can all be assessed directly in situ. Once cultures are complete, models can be released from their inserts and processed using standard downstream assays, including histology, imaging, protein analysis, and gene expression studies. Importantly, the platform has been engineered for compatibility with instrumentation already used in the clinic to monitor skin physiology. This alignment between in vitro and clinical testing increases translational relevance, allowing preclinical results to better inform trial design and potentially reducing costs and development timelines.

A Complement to Existing Alvetex® Systems

Alvetex® Advanced has been created to expand, rather than replace, the existing Alvetex® range. Current products remain fully suited to many applications in tissue engineering and toxicology, while the new system provides enhanced control and broader functionality for projects that demand greater flexibility or integration with advanced instrumentation. By offering researchers both options, the platform ensures that the most appropriate tool is available for every experimental requirement.

Conclusion

Alvetex® Advanced represents a significant step forward in engineered skin technology. By combining scaffold performance with a refined and adaptable culture system, it enables researchers to generate more biologically accurate models while expanding the range of applications that can be performed in vitro. This new platform strengthens the link between laboratory research and clinical practice, positioning it as an essential addition to the Alvetex® product portfolio.